The Duty of Modern Technology in Modern Welding Inspection Madison Practices

The Duty of Modern Technology in Modern Welding Inspection Madison Practices

Blog Article

Comprehending the Fundamentals of Welding Inspection to Ensure Quality and Safety And Security

In the realm of modern-day engineering, welding examination stands as a keystone for making certain both the high quality and security of structural developments. What are the subtleties of these assessment techniques that make them essential for preserving structural integrity?

Significance of Welding Inspection

In the realm of commercial fabrication, the importance of welding evaluation can not be overstated. Welding assessment plays an essential duty in ensuring the integrity, safety and security, and longevity of welded structures. Given the diverse applications of welding in industries such as construction, automobile, aerospace, and shipbuilding, the need for rigid quality assurance steps is vital. Appropriate evaluation guarantees that welds meet specified standards and codes, which is vital for protecting against architectural failures that could lead to catastrophic effects.

The process of welding inherently involves intricate variables, including temperature, product buildings, and ecological problems, all of which can affect the top quality of the weld. A complete examination determines issues such as fractures, porosity, and insufficient combination, which can compromise the stamina and dependability of the weld. By identifying these issues early, corrective actions can be taken, thus decreasing the threat of failure and connected costs.

Additionally, welding inspection contributes to regulatory conformity, as numerous industries are controlled by rigorous safety standards and guidelines. Failing to comply with these laws can result in monetary penalties and lawful obligations. Eventually, welding examination not just safeguards physical frameworks yet likewise supports and protects human lives industry online reputations.

Secret Welding Inspection Methods

Although welding inspection is critical to making certain the top quality and security of welded frameworks, it is the certain techniques employed that establish the efficiency of the evaluation procedure. Secret welding evaluation approaches can be extensively categorized right into non-destructive testing (NDT) and destructive screening.

Magnetic bit screening and liquid penetrant screening are surface area evaluation approaches used to find surface area and near-surface imperfections. These extensive examination approaches ensure that welds meet market requirements and security needs, therefore ensuring structural integrity and efficiency.

Role of Licensed Examiners

Licensed examiners play an essential function in the welding assessment procedure, ensuring that all welds adhere to rigid market requirements and security policies. Their know-how is crucial in determining flaws or abnormalities that may jeopardize the structural integrity of a weld. By diligently checking out each weld, licensed examiners assist protect against prospective failings that might cause harmful accidents or costly fixings.

To come to be licensed, inspectors have to go through rigorous training and screening, which acquaints them with different welding techniques, products, and testing methods. This thorough understanding allows them to review weld high quality effectively and make educated judgments regarding their safety and integrity. Additionally, certified examiners excel in interpreting specs and blueprints, making sure that the welding work straightens with the project's layout requirements.

An integral part of their role is to document their findings thoroughly, offering an in-depth document of the examination procedure. Their payment is indispensable in maintaining high levels of quality and safety in welding operations.

Tools Used in Welding Inspection

Welding assessors count on a range of specialized tools to execute their obligations successfully, guaranteeing each weld satisfies the essential criteria. Among these devices, aesthetic examination help like magnifying glasses and mirrors are basic, enabling assessors to closely check out welds for surface area flaws such as cracks, porosity, and undercut. Calipers and fillet weld determines are crucial Homepage for determining weld measurements to confirm compliance with design requirements.

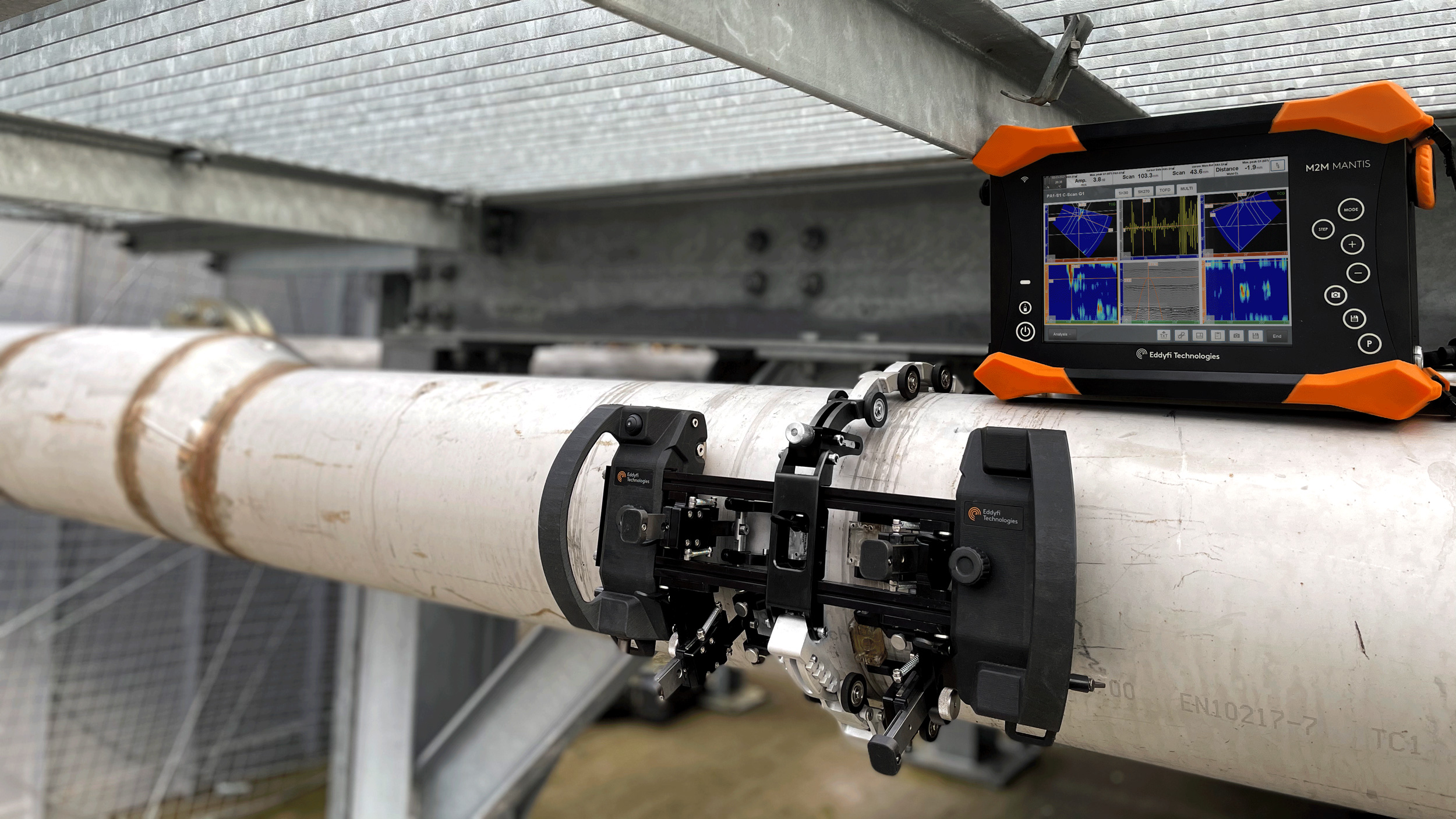

Advanced tools prolong past visual help, including non-destructive screening (NDT) equipment. Ultrasonic screening devices are crucial in finding subsurface defects, making use of acoustic waves to disclose internal stoppages without jeopardizing the weld's integrity. Radiographic screening uses X-rays or gamma rays to capture pictures of a weld's interior, highlighting prospective issues.

Magnetic bit screening is another important device, particularly for finding surface and near-surface gaps in ferromagnetic products. By applying electromagnetic fields and ferrous fragments, examiners can recognize imperfections that might otherwise be undetectable.

Dye penetrant inspection is frequently utilized for non-ferrous products, providing a contrast-enhanced aesthetic look for surface-breaking issues. Welding Inspection Madison. Together, these tools enable welding examiners to thoroughly analyze weld quality, making sure safety and reliability in different applications across markets

Making Sure Architectural Honesty

Welding treatments should follow well established standards and codes, such as those defined by the American Welding Society (AWS) or the International Company for Standardization content (ISO) These standards make certain that the welds can stand up to operational stress and anxieties and environmental variables. Qualified and licensed welders play a vital role in this procedure, as their know-how ensures that strategies are applied correctly, decreasing problems such as fractures, porosity, and insufficient blend.

Post-weld assessment is one more crucial part of verifying structural integrity. These inspections validate that the welds meet the required high quality requirements, offering assurance of their toughness and dependability.

Verdict

The fundamentals of welding inspection are essential for preserving the high quality and safety and security of bonded structures. The usage of specialized tools additionally enhances the assessment process, eventually safeguarding human lives and extending the life expectancy of bonded buildings.

Welding examination plays a vital role in guaranteeing the honesty, safety, and durability of bonded structures.Although welding assessment is critical to guaranteeing the top quality and safety of welded frameworks, it is the details methods utilized that establish the effectiveness of the evaluation procedure. website here Trick welding inspection techniques can be extensively classified right into non-destructive screening (NDT) and destructive screening.Qualified assessors play an essential role in the welding assessment procedure, ensuring that all welds comply with strict market requirements and safety and security laws.The principles of welding examination are vital for maintaining the quality and security of welded frameworks.

Report this page